Nine9 spot drills

Advanced Carbide Tooling are the UK’s exclusive distributor of Nine9 spot drills.

NC spot drills have an indexable carbide insert providing efficiency benefits and cost savings for CNC lathes, CNC turning centres and machining centres. One tool will perform multiple applications.

Features and benefits include:-

- Long tool life

- Each insert has up to four cutting edges

- Suitable for spotting, chamfering, grooving and engraving

- 60˚, 82˚, 90˚, 100˚, 120˚ and 142˚ angles are available for different applications

- Increased cutting speeds are provided by coated carbide inserts.

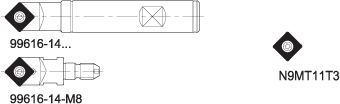

60˚ NC Spot drill

Spotting diameter 2~5. Applications: spotting, chamfering and engraving.

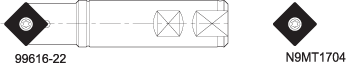

Spotting diameter 2~13. Applications: spotting, chamfering and V-grooving.

82˚ NC Spot drill

Spotting diameter 2~9. Applications: spotting, chamfering and V-grooving.

Spotting diameter 2~14. Applications: spotting, chamfering and V-grooving.

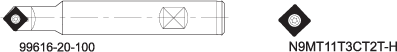

90˚ NC Spot drill

Spotting diameter 1~6. Applications: spotting, chamfering and engraving.

Spotting diameter 2~10. Applications: spotting, chamfering, V-grooving and engraving.

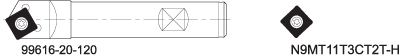

Spotting diameter 3~14. Applications: spotting, chamfering, V-grooving and engraving.

Spotting diameter 3~22. Applications: spotting, chamfering and V-grooving.

Spotting diameter 4~25. Applications: spotting and chamfering.

100˚ NC Spot drill

Spotting diameter 4~16. Applications: centering and chamfering.

120˚ NC Spot drill

Spotting diameter 4~17. Applications: centering and chamfering.

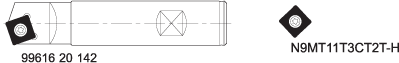

142˚ NC Spot drill

Spotting diameter 4~18. Applications: centering and chamfering.

Video: Nine9 NC Spot Drill

Download the Nine9 brochure

Nine9 spot drills, corner rounding cutters and chamfering cutters brochure.

Download brochure »This 1.5 MB 24 page leaflet is available to download and includes the following information:-

- Tool versatility

- NC spot drill mini

- Spot drill and holder information

- Inserts

- Drill sets

- Corner rounding cutters

- Chamfering tools

- Diameter and depth chart

- Cutting data