Sliding head solutions from Dieterle

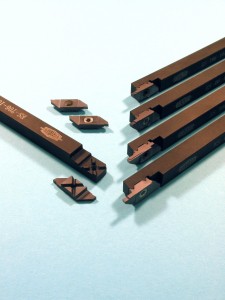

A comprehensive range of tooling manufactured by Dieterle, Germany covers all aspects of ‘Sliding head’ operations.

Fast metal removal whether plunge grooving, side turning, or external grooving, Dieterle can offer a cost effective solution.

A comprehensive range of small internal boring tooling is also available.

Our UK manufactured ACT2.2 and Microcut also support our tooling range for ‘Sliding Head Operations’ with parting off widths 0.5mm, 0.8mm, 1.1mm, 1.6mm & 2.2mm wide.

There are many tooling manufacturers offering a wide range of tools and inserts for sliding head machine tool applications. Unfortunately there are few tooling systems which reflect the specific needs or requirements of automatic lathes.

For more than 30 years Dieterle has exclusively been producing tools for automatic lathes. Dieterle website »

For more than 30 years Dieterle has exclusively been producing tools for automatic lathes. Dieterle website »

Consider the following features which benefit customers using Dieterle:

- Only hardened or high-yield-point material is used in the production of Dieterle tool holders.

- A full range of shank dimensions and a variety of lengths are available to meet all requirements.

- Inserts offered are ground all over or completely sintered. A high precision in interchanging and indexing of inserts is always achieved.

- 0 – 0.8 mm corner radii are available.

- Various insert geometries and carbide grades including cermet are available to cater for all types of material and chip control, particularly for high-alloy and stainless steels.

- Unique insert fixing simplifies cutting edge indexing.

All the tools of Dieterle’s internal machining range fit in length and diameter to the toolholders of the most commonly used CNC-turret and cam-controlled lathes. Thanks to Dieterle’s heavy-metal holders even the smallest diameters can be machined, free from vibration and with high precision.