Parting off and grooving tool

Parting off and grooving tool

ACT 2.2 is ideal for parting off up to 42mm diameter, precision grooving, light turning and facing.

Features, advantages and benefits include:-

Mechanically clamped insert improves rigidity and repeatability.

- Full side reinforcement to blade ensures flat components when parting off.

- Integral shank design for strength manufactured to ISO standards on size.

- Stepped down blade design extends insert and tool life.

- Special tool holders ( using Standard Stock inserts) made to customers individual requirements on request.

- Special inserts manufactured to customer needs.

The four-in-one tooling system is suitable for the following applications:-

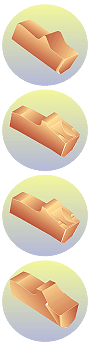

NDC radial grooves /face grooving applications 10° pos. top rake (top right)

NBC cut-off, radial grooves Strong 9° neg. chip controller for general parting off applications(second right)

NEC cut-off, radial grooves–positive chip breaker – 1st Choice for parting off all materials including Stainless Steels, Titanium, Alloy Steels (third right)

NAC2-H cut-off, radial grooves Carbide High Shear TiN 25° pos. high shear. Ideal for aluminium,plastics, acrylic (bottom right).

The ACT 2.2 leaflet is available to view below (please allow a moment for it to load) and includes the following information:-

- Cutting data for parting off and external grooving

- Technical specifications on tool holders

- Tool holders for automatics

- Table showing entry length for type 121C

- Technical specifications on carbide inserts

- Technical specifications on HSS TiN inserts

- Special ground inserts.

Parting off and grooving tool

Parting off and grooving tool Mechanically clamped insert improves rigidity and repeatability.

Mechanically clamped insert improves rigidity and repeatability.